Why Finishing Techniques Matter in Feather Flag Printing

Innovative Finishing Techniques in Flag Printing Industry

In the highly competitive world of flag printing, the use of innovative finishing techniques can make a significant difference in the quality and durability of the final product. One such technique that has gained popularity in recent years is the heat-sealing technology. This method involves using heat to bond the edges of the flag material, creating a strong and seamless finish that not only enhances the overall look but also ensures longevity.

Another innovative finishing technique that has proven to be effective is the use of specialised coatings that offer protection against UV radiation and weather elements. These coatings not only help in preserving the vibrancy of the colours used in the flag but also increase the flag's resistance to fading and damage over time. By employing these cutting-edge techniques, flag printing companies can offer their clients flags that are not only visually appealing but also durable and long-lasting.

HeatSealing Technology

Heat sealing technology plays a crucial role in the flag printing industry, providing a durable and professional finish to feather flags. By using heat and pressure, the fabric edges are sealed, preventing fraying and ensuring longevity. This technique not only enhances the overall look of the flag but also contributes to its structural integrity, making it more resistant to wear and tear.

Flags that are heat-sealed exhibit clean and crisp edges that give a polished appearance. This meticulous finish is essential for outdoor flags exposed to various weather conditions, as it helps maintain the flag's shape and quality over time. With heat sealing technology, businesses can create eye-catching feather flags that not only attract attention but also withstand the elements for prolonged use.

Considerations for Choosing the Right Finishing Technique

When it comes to choosing the right finishing technique for your feather flags, there are several key considerations to keep in mind. Firstly, it is crucial to assess the durability and longevity of the finishing technique. The finishing used should be able to withstand various weather conditions, ensuring that your flags remain vibrant and intact for extended periods.

Another important factor to consider is the cost-effectiveness of the finishing technique. While it is essential to invest in high-quality finishing for your feather flags, you also need to ensure that it fits within your budget constraints. Conducting thorough research on different finishing options and their respective costs can help you make an informed decision that aligns with your financial resources.

Environmental Sustainability

Environmental sustainability is a crucial factor to consider when selecting finishing techniques for feather flag printing. As the global focus on reducing environmental impact continues to grow, businesses are increasingly seeking out eco-friendly options to align with their values and meet consumer expectations. In the flag printing industry, adopting sustainable practices not only helps to minimise harm to the environment but also demonstrates a commitment to responsible business operations.

One of the key considerations for environmental sustainability in finishing techniques is the use of water-based inks and coatings. These alternatives to traditional solvent-based products are more environmentally friendly, emitting lower levels of volatile organic compounds (VOCs) that can contribute to air pollution and harm human health. By opting for water-based finishes, flag printing companies can reduce their carbon footprint and contribute to a cleaner, greener future for all.

Impact of Finishing Techniques on Brand Visibility

Finishing techniques play a crucial role in enhancing brand visibility through feather flag printing. By utilising innovative finishing methods, businesses can elevate the overall look and appeal of their flags. A well-executed finish not only ensures longevity but also helps in creating a lasting impression on viewers. This is particularly important in outdoor settings where flags are exposed to various elements, making a durable and eye-catching finish essential for maintaining brand visibility.

The choice of finishing technique can have a significant impact on how a brand is perceived by its audience. From vibrant colours that pop to a smooth and professional appearance, the finishing touch can make a world of difference in attracting attention and conveying a sense of quality and reliability. By investing in the right finishing techniques, businesses can effectively communicate their brand message and stand out in crowded environments, ultimately boosting brand visibility and recognition.

Colour Retention

When it comes to feather flag printing, colour retention is a crucial aspect that should not be overlooked. The ability of a flag to maintain its vibrant colours over time is essential for ensuring that your brand remains visible and impactful. Given that feather flags are often placed outdoors where they are subjected to various weather conditions, the choice of finishing technique plays a significant role in determining how well the colours will hold up.

One of the key factors that influence colour retention in feather flag printing is the type of ink used in the process. High-quality UV-resistant inks are essential for ensuring that the colours on the flag remain vivid and fade-resistant, even when exposed to harsh sunlight. Additionally, the application of a protective coating as part of the finishing process can also contribute to enhancing colour retention by providing an extra layer of shielding against environmental factors. By investing in the right finishing techniques that prioritise colour retention, you can ensure that your feather flags continue to showcase your brand effectively for a prolonged period.

FAQS

Why are finishing techniques important in feather flag printing?

Finishing techniques are crucial in feather flag printing as they enhance the durability and visual appeal of the flags, making them more effective in attracting attention and conveying brand messages.

What is heat-sealing technology in flag printing?

Heat-sealing technology is a method used in flag printing to seal the edges of the fabric, preventing fraying and ensuring a neat finish that prolongs the flag's lifespan.

How can environmental sustainability be achieved in flag printing finishing techniques?

Environmental sustainability in flag printing finishing techniques can be achieved by using eco-friendly materials, processes, and practices that reduce the carbon footprint of flag production.

How do finishing techniques impact brand visibility in feather flag printing?

Finishing techniques play a significant role in brand visibility as they affect the overall appearance and quality of the flags, influencing how effectively they communicate the brand message and attract attention.

What role does colour retention play in finishing techniques for feather flag printing?

Colour retention is an essential consideration in finishing techniques for feather flag printing as it ensures that the vibrant colours of the flags remain intact over time, maintaining the flag's visual impact and brand recognition.

Related Links

What Factors Affect Colour Matching in Feather Flag PrintingWhy Quality Control is Important in Feather Flag Printing

Roundup: Latest Trends in Feather Flag Printing

The Evolution of Feather Flag Printing

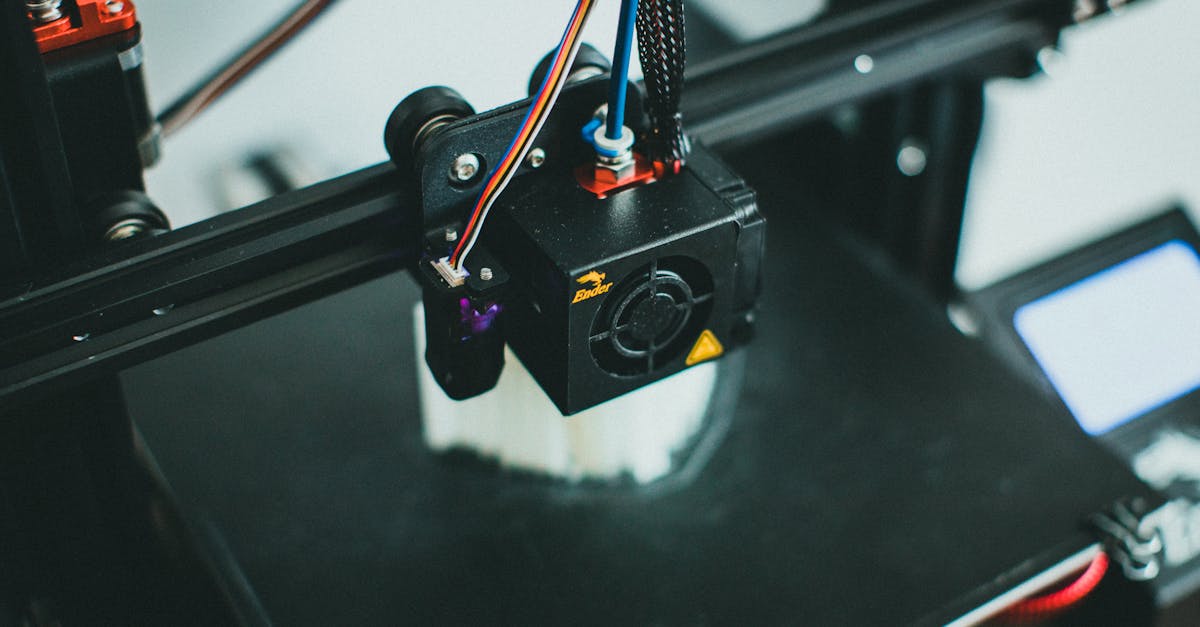

Review of the Best Printing Equipment for Feather Flag Printing

Top 10 Materials for Feather Flag Printing