Why Quality Control is Important in Feather Flag Printing

Ways to Ensure HighQuality Feather Flag Printing

Ensuring high-quality feather flag printing is essential for businesses looking to make a strong visual impact with their promotional materials. One way to achieve this is by investing in top-notch printing equipment and regularly maintaining its efficiency. By keeping your printers and related machinery in optimal condition, you can consistently produce crisp and vibrant prints that meet your clients' expectations.

Another key aspect to consider is the materials used in the printing process. Opting for high-quality inks and fabrics can significantly enhance the final output of your feather flags. By selecting the right combination of materials, you can ensure that your prints have excellent adhesion and coverage, resulting in sharp designs that effectively communicate your message to a wider audience.

Maintaining Printing Equipment Efficiency

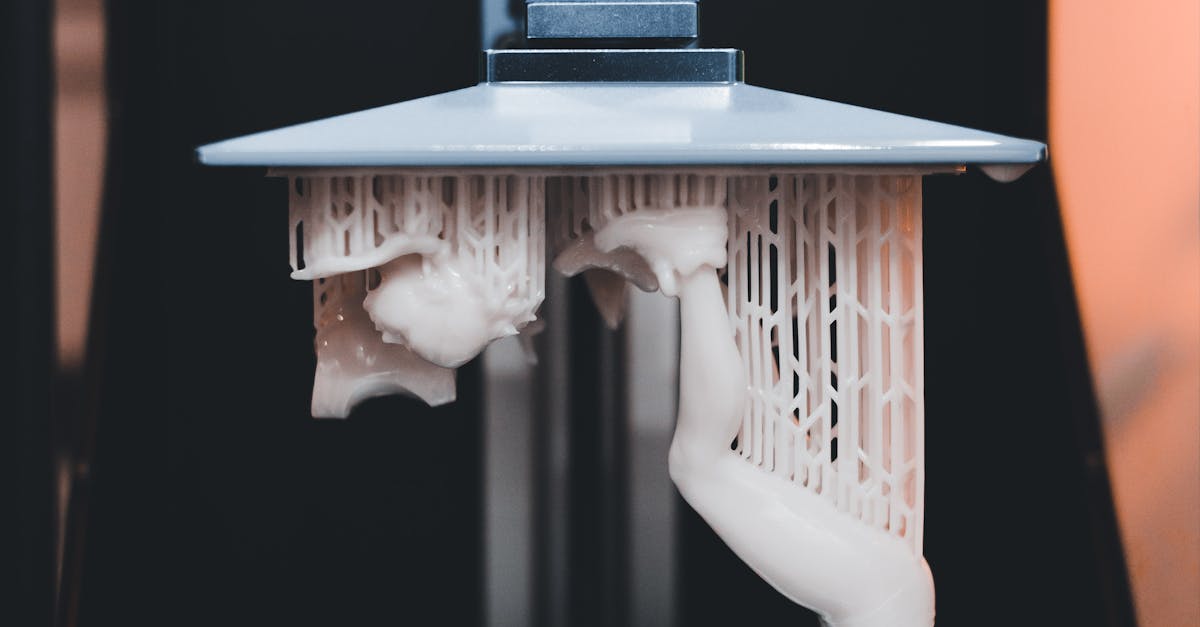

To maintain printing equipment efficiency in the feather flag printing business, regular maintenance and cleaning routines are crucial. Cleaning print heads, inspecting ink levels, and ensuring proper calibration of the machines are essential tasks to uphold the quality of the final product. Neglecting these maintenance procedures can lead to poor print quality, wasted materials, and costly repairs in the long run.

Another key aspect of maintaining printing equipment efficiency is investing in high-quality materials and components. Using substandard inks, papers, or fabrics can cause clogs, streaks, and inconsistent colour reproduction, which can negatively impact the overall printing process. By prioritising the use of reliable supplies and equipment, businesses can optimise their printing processes and deliver consistent, high-quality feather flags to their customers.

Quality Control Techniques for Flag Printing Businesses

Some common quality control techniques that flag printing businesses can implement to ensure high standards include regular checks on colour accuracy and consistency, as well as inspecting for any misprints or defects. Utilising quality control software and tools can help to streamline this process, making it easier to identify and rectify any issues that may arise during the printing process.

Another effective technique is to conduct thorough inspections of the materials used for printing, such as the fabric of the flags and the type of ink being applied. By maintaining strict guidelines for material quality and ink adherence, businesses can prevent potential issues like fading colours or bleeding ink. Additionally, setting up a system for tracking and documenting the printing process can help to maintain consistency and quality throughout each batch of feather flags produced.

Controlling Ink Adhesion and Coverage

Ink adhesion and coverage are critical aspects of feather flag printing that directly impact the quality of the final product. Proper control of ink adhesion ensures that the colours adhere to the fabric surface effectively, resulting in vibrant and long-lasting prints. Insufficient adhesion can lead to colours fading quickly or even peeling off, diminishing the overall visual appeal and durability of the feather flags.

To maintain consistent ink coverage, flag printing businesses must carefully monitor and adjust the printing process. Uneven ink coverage can result in patchy or streaked prints, detracting from the professional appearance of the flags. By implementing quality control measures such as adjusting printing pressures, speeds, and temperatures, businesses can ensure that each feather flag receives uniform and thorough ink coverage for a high-quality final product.

Impact of Quality Control on Overall Printing Standards

Quality control plays a crucial role in maintaining high standards in feather flag printing. By implementing stringent quality control measures throughout the printing process, flag printing businesses can ensure that each flag produced meets the required quality standards. This not only enhances the overall printing standards of the business but also helps in establishing a reputation for delivering top-notch products to customers.

Consistent quality control practices lead to improved efficiency and productivity within the printing process. By detecting and rectifying errors early on, businesses can avoid costly reprints and wastage of resources. Ultimately, the impact of quality control on the overall printing standards is reflected in the satisfaction of customers who receive flawless and professionally printed feather flags.

Improving Finishing Techniques

To enhance the overall quality and appeal of feather flags, improving finishing techniques is crucial for printing businesses. A polished finish not only elevates the visual impact of the flag but also reflects positively on the professionalism of the business. One effective way to improve finishing techniques is to invest in high-quality cutting tools that can produce clean and precise edges. This will ensure that the flag has a neat and professional appearance, enhancing its overall attractiveness and quality.

Furthermore, paying attention to detail when hemming and stitching the edges of the flag can make a significant difference in its final presentation. Using strong and durable thread will help ensure that the hemming is secure and long-lasting, preventing fraying and ensuring that the flag maintains its quality over time. By focusing on refining these finishing techniques, flag printing businesses can deliver products that meet high standards of quality and durability, ultimately setting them apart in the competitive market.

FAQS

Why is quality control important in feather flag printing?

Quality control is important in feather flag printing to ensure that the flags meet the desired standards of durability, colour accuracy, and overall visual appeal.

How can businesses ensure high-quality feather flag printing?

Businesses can ensure high-quality feather flag printing by maintaining printing equipment efficiency, controlling ink adhesion and coverage, and improving finishing techniques.

What are some quality control techniques for flag printing businesses?

Some quality control techniques for flag printing businesses include regular maintenance of printing equipment, conducting colour accuracy checks, and inspecting the flags for any defects before shipping.

How does quality control impact overall printing standards?

Quality control helps in maintaining consistency in the printing process, ensuring that every feather flag meets the required quality standards, thereby enhancing the overall reputation and customer satisfaction of the business.

How important is maintaining printing equipment efficiency in quality control?

Maintaining printing equipment efficiency is crucial in quality control as it directly impacts the consistency and accuracy of the printing process, leading to high-quality feather flag output.

Related Links

Why Finishing Techniques Matter in Feather Flag PrintingWhat Materials are Used for Feather Flag Printing

Roundup: Latest Trends in Feather Flag Printing

The Evolution of Feather Flag Printing

Review of the Best Printing Equipment for Feather Flag Printing

Top 10 Materials for Feather Flag Printing

What Factors Affect Colour Matching in Feather Flag Printing

How to Maintain Printing Equipment for Feather Flag Printing

How to Choose the Right Printing Equipment for Feather Flag Printing